L

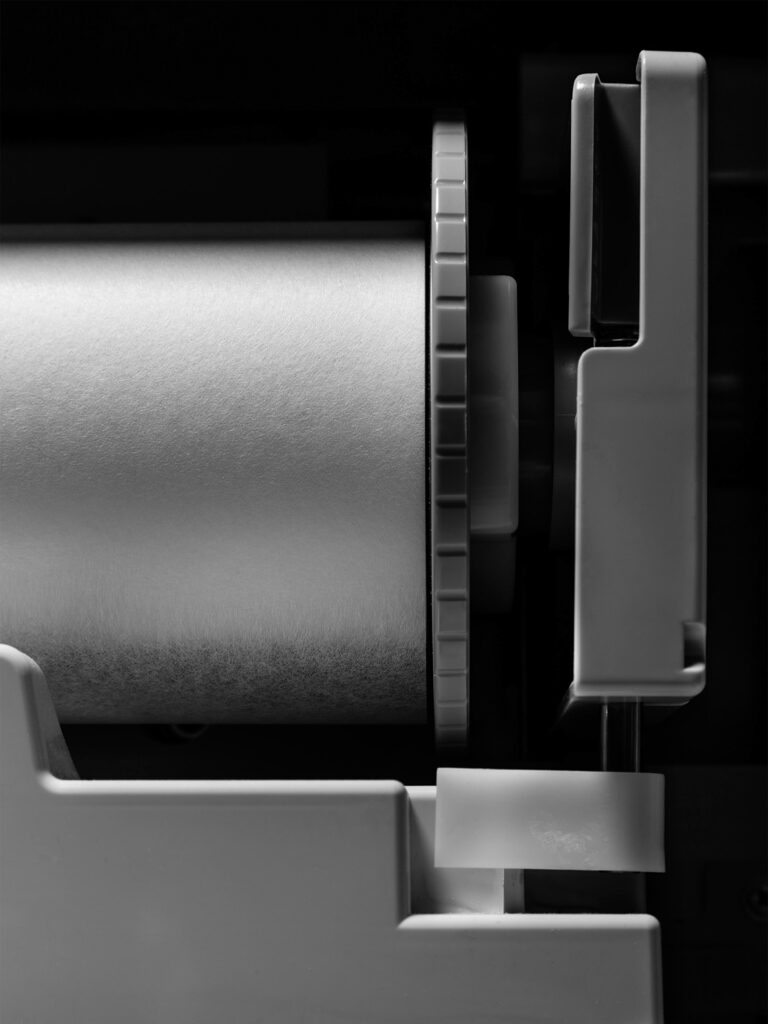

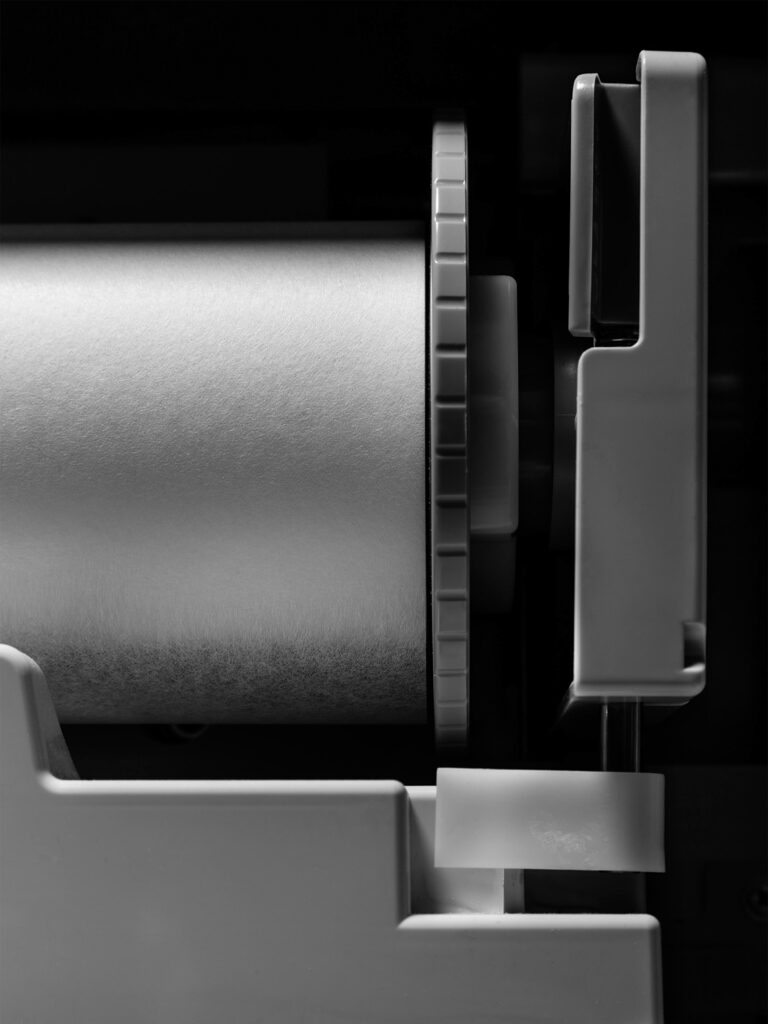

In 1982, the new machines were first shown at CeBIT Hannover and in 1984 at NOMDA, a major office equipment fair in the US. In both cases, the printers were consistently well received. In the same year, the first fully automatic machine was released: the Risograph 007. This included a master making unit that was automatically able to attach the created master to the print cylinder, which proved to be another advantage for the print method: From now on, it was possible to create copies of printed documents via a glass template without knowing about print cylinders, master foils and colour cartridges. In 1986, this was extended by a digital unit that could be controlled from the computer. The company expanded to America, Europe and Africa. Today, RISO printers are used in 180 countries and regions worldwide and account for the largest share of digital duplicators in the marketplace. Increasing digitisation and connection to word processors or personal computers were a great help in promoting the spread of risography.

In 1995, Japan was struck by the Great Hanshin earthquake and suddenly, the risograph played a very important role in spreading news: Since large newspapers were unable to print their editions on large printing presses, the risograph was widely used. In 1999, Akira Hayama, the son of Noboru Hayama, took on the position of President and Representative Director to revolutionise the company once again. While coloured stencil devices were already in use in 1999, RISO decided to make printing with colour more affordable again. In cooperation with Olympus, a high-speed colour inkjet printer was developed: the RISO HC 5000. On the first day of sale, it reached a new world record in print speed, printing 105 pages a minute. It remains the world’s fastest printer to date. Not only was it very fast, its economic performance was revolutionary, while still printing at the same quality level like established black and white printers. In 2001, the risographic print method was reimagined again by the use of soybean oil-based colour, and since 2004, the two-colour MZ system has been in use. In 2007, the handheld scanner Scamo was released: a small scanner that allows the user to scan virtually any object up to the size of a postcard. Among other things, RISO which produce brilliant and fast results. However, these machines rely on four-colour toner cartridges and thus on autotypical colour synthesis, which is why these printers are neglected in this publication as they are closly related to conventional inkjet printers.

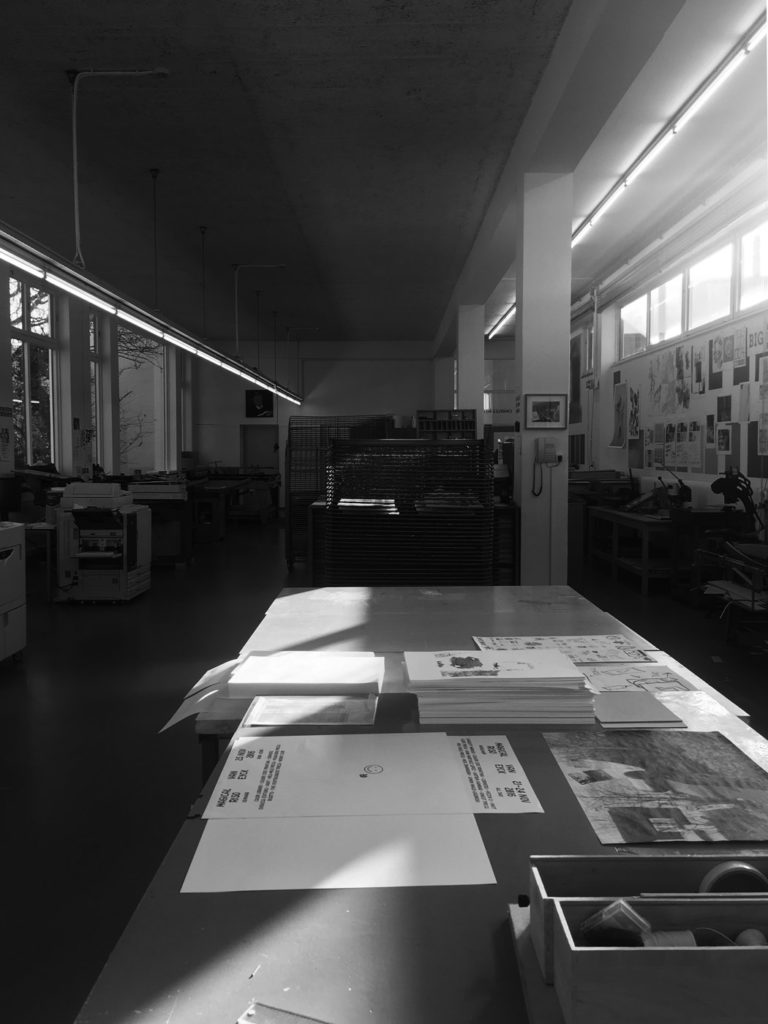

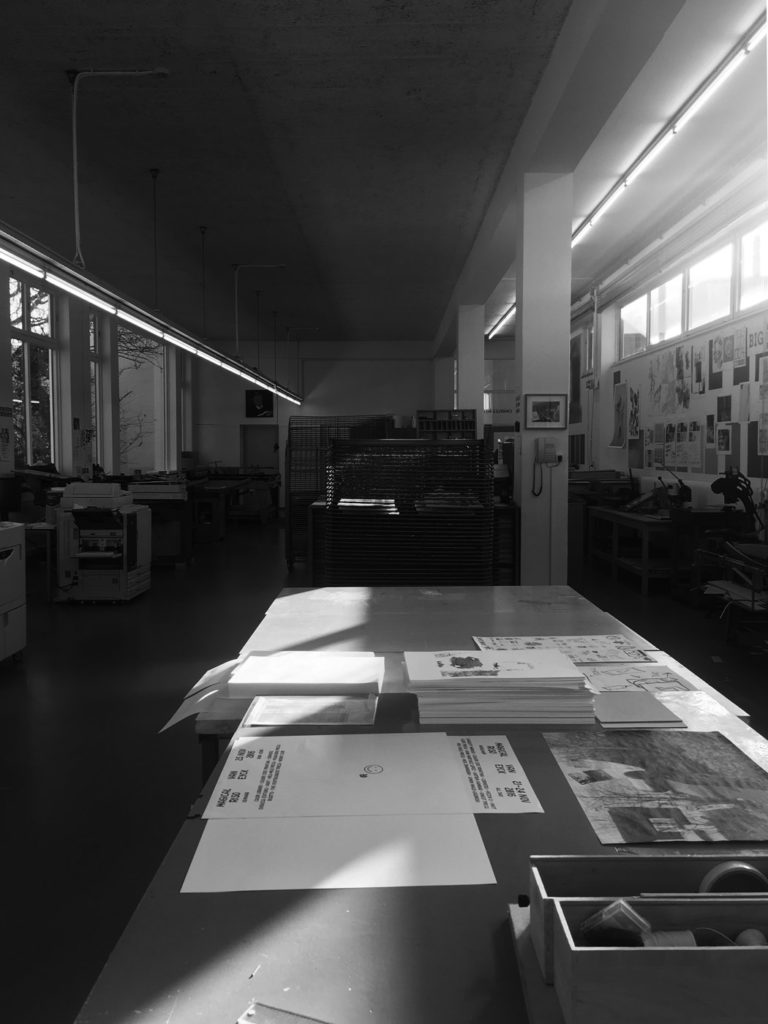

In 2013, the first digital duplicator that can print in the A2-sized format was introduced, the most common format in the printing industry according to RISO 63. However, the machine officially only works with grammages of up to 120 g / m2, which makes the RISO A2 especially suitable for the reproduction of tabloid newspapers (285 400 mm). One of these RISO A2 machines is located at the Van Eyck Academie in Maastricht. A partnership with RISO Benelux enabled the Van Eyck Academie to set the printer up and put it into operation in one of its workshops, the Printing and Publishing Lab (then known as Charles Nypels Lab), that welcomes artists, writers, designers, photographers, poets, scientists and essayists to develop and print their work here.

1

Das Charles Nypels Lab in Maastricht (NL)

1

Das Charles Nypels Lab in Maastricht (NL)

1

1

2

2

1

1

2

2